Scope of the executed works:

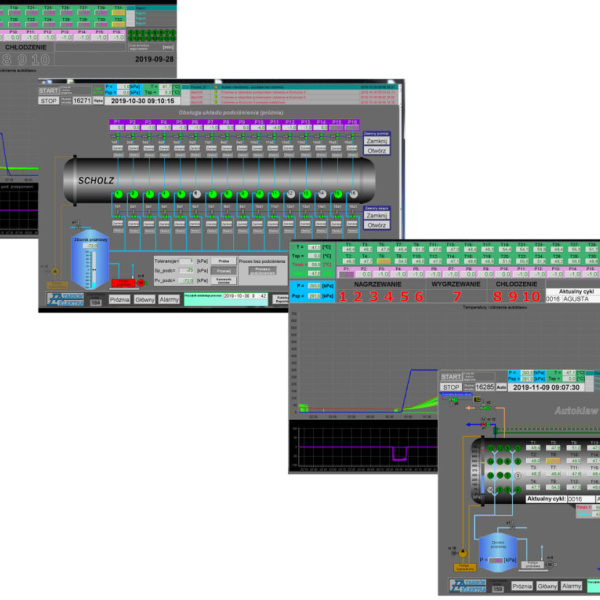

Complete service of the electrical installation and instrumentation of the autoclave no. 1 SCHOLZ at the W 360 department

Mechanical works

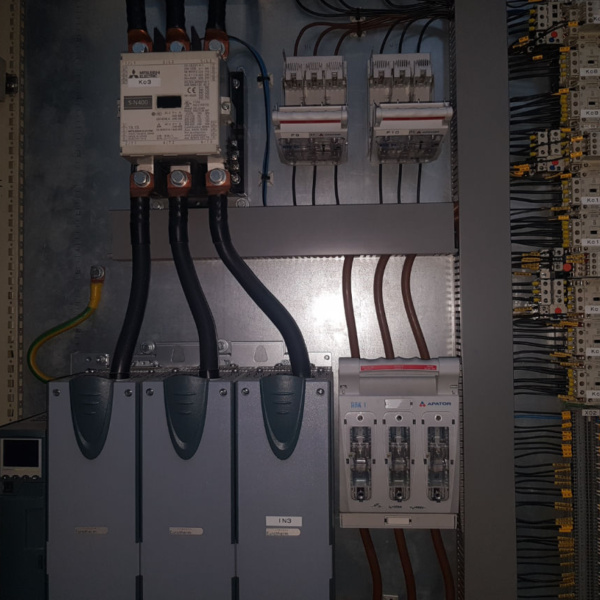

- Checking the correct tightening torque of screws in medium and high current circuits and correcting them by cleaning the contacts and applying conductive paste.

- Inspection, cleaning or possible replacement of filters in power supply and control cabinets.

- Inspection of the compressed air installation in terms of tightness of the system and the efficiency of the air preparation system.

- Inspection of the vacuum system, including the patency of tubes and filter cartridges.

Electrical works

- Checking the correct operation of digital signals, including control from the level of visualization and PLC controller.

- Checking the correct operation of electrical protections.

Measurements and calibration

- Measurements of the resistance of the main current paths of the power supply and heating systems, including connections, using a meter for measuring small resistances with a resolution of up to 1 [μΩ]

- Checking the temperature measurement paths – thermocouple sensors using a transmitter.

- Calibration of transducers in temperature measurement paths – thermocouple sensors.

- Checking the temperature measurement paths – PT100 sensors using a decade resistor.

- Checking the pressure and vacuum measurement paths using a transmitter.

- Corrective software changes in the PLC at the request of the staff, after prior approval of the need for these changes by the Customer’s representative.

- Minor changes to the PC software (ASIX visualization) at the request of the staff, after prior approval of the need for these changes by the Customer’s representative.

- Final thermal imaging measurements of elements in power supply and instrumentation cabinets during the polymerization process.